A Guide to Closing Efficiency Gaps in an Order Fulfillment System

More orders. Faster delivery. A complex, global supply chain.

Managing order fulfillment systems and processes in today’s global business world is more challenging and multi-faceted than ever before. The efficiency and reliability in your packaging and distribution systems are directly tied to customer satisfaction, future opportunity and the overall bottom line.

Supply Chain Council defines perfect order fulfillment as “the percentage of orders meeting delivery performance with complete and accurate documentation and no delivery damage.” While this concept is straightforward, the council found many manufacturers and distribution centers struggle to accomplish this goal.

Why? The leading barriers are outdated, disconnected and inefficient processes and systems in order fulfillment and document insertion. Many systems are not yet capable to meet the increased demand and lack real-time data for efficient decision-making and quick adjustments.

The bar is set high. Efficiency must be higher.

How to Evaluate Systems to Maximize Efficiency

Determining how to close inefficiencies in an order fulfillment system will be unique to each Distribution Center and integrator. The most effective route when upgrading or adding systems is a customized solution that is aligned to your precise need, individual KPIs and goals. However, there are three key areas where barriers often occur and opportunities exist for gains in efficiency and competitive edge.

Key Areas of Opportunity

Adaptability It’s critical to keep order fulfillment systems running at peak performance, especially during times of high demand and frequent fluctuations. Evaluate:

- If a workflow suddenly changes, can your system be adjusted quickly and reliably to meet demand?

- Do you have automated systems that can be easily programmed for workflow adjustments? Or, do you have inefficient time spent in training or bringing on additional workers?

- Do you have inefficient time spent moving material from one system to another when changes occur?

Automation Fewer systems lead to less downtime, less capital expense and greater efficiency. Through automated technology, you can gain accuracy and productivity, resulting in more opportunity for repeat business, upsell and referral business.

- Evaluate where cost reductions need to be made in production, line errors, labor costs and system downtimes.

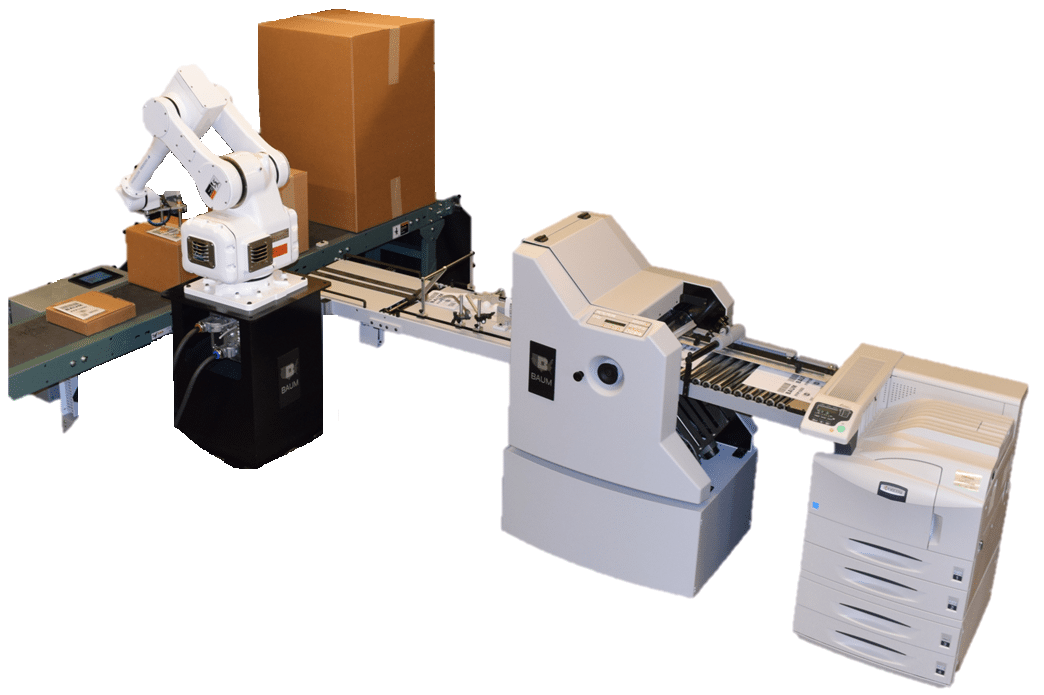

- Determine where an automated solution, such as for high-speed printing, folding and document insertion or print and apply application, could lead to improvements in order accuracy, productivity and overall customer satisfaction.

- Assess where opportunity exists to integrate two systems into one more efficient system with automation.

Durability Heavy duty commercial manufacturing solutions are proven to last longer and have fewer maintenance requirements, therefore, equaling less down time and overall costs. To your customer, these means reliability.

- Evaluate where a more robust system that is also modular in design to suit many variables in applications could provide opportunity and reliability.

Get a free Efficiency Checklist and a printable pdf of this guide, Closing Efficiency Gaps in an Order Fulfillment System. Use the 1-page checklist as a guide to streamlining an order fulfillment system for maximum efficiency, reliability and customer satisfaction.

How to Calculate ROI of Solutions

Closing the gaps in efficiency involves calculating ROI on system upgrades or replacements. In most scenarios, an upgraded order fulfillment solution pays for itself in at least a year. Many see ROI even sooner as service and operational levels improve while costs are cut.

When calculating an estimated ROI of an order fulfillment solution, take into consideration these key areas:

Key Areas to Calculating ROI

Throughput. How much more can you get out per day, per line? What additional capabilities can an upgrade or re-engineered order fulfillment solution provide that can increase yearly throughput?

- Use industry ROI formulas to help you accurately evaluate investments and necessary components. For example, determine personalized document insertion per carton using: cartons per minute x number of documents printed x 60 (minutes hour) x operational hours per year = copies printed per year.

Labor Costs. The largest expense in packaging and distribution is labor. Automated order fulfillment solutions improve productivity and accuracy while reducing labor costs and challenges due to employee turnover, training and human error.

Waste. An efficient order fulfillment solution can open space on the floor and recover areas for additional operations. Travel time and duplicate touches due to separate systems can also be eliminated with a solution-based system that maximizes space and efficiency.

Accuracy. Customer expectations are for 100% accuracy. When not achieved, there are added costs and a reduced customer service level. When calculating the costs of inaccuracy, costs must include any necessary reshipping, restocking, production delays, use of resources to resolve errors, and additional end-user delays or missed opportunities.

Capabilities. Compare current capabilities to additional capabilities gained with a new or upgraded solution. Can a new solution provide immediate added capabilities, such as barcode verification or customized document insertion, to achieve ROI even faster? Will an upgraded solution be easily compatible with future technologies and advancements to continue to capitalize on ROI?

Consumables. Look beyond the cost of the equipment. What is your costs per printed page? What additional costs do you have in special envelopes, mailing sleeves and other shipping pouches compared to the costs of document insertion and/or print and apply?

Maintenance Costs. When overall system costs are inefficient and too high, you lose competitive edge by impacting sales and the company bottom line. Continued maintenance costs can also sidetrack new technology and lead to falling even further behind. The durability of the equipment within the solution directly ties to ROI.

Choosing a Solution Provider

A valuable solution provider goes above and beyond selling and installing order fulfillment equipment. Value is added when a provider offers a customized approach that involves a thorough efficiency evaluation of your current system and processes to find key areas for opportunity and ROI. While researching equipment and quotes, look for a solution provider that also excels in these areas:

Key Areas when Comparing Solution Providers

- Capabilities. Does the provider go above and beyond selling and installing equipment? Can they provide support and guidance in evaluating and diagnosing inefficiencies, barriers and problem areas in current solutions? Will they provide expert recommendations based on key findings vs. quoting only what is requested? Can they integrate new systems with your current systems? Will they provide a hands-on demonstration and samples of print and apply and document insertion solutions?

- Durable and Reliable Equipment. Are they known for robust equipment? Do they have years of design and manufacturing experience? Do they offer equipment that is industrial grade vs. office setting? What partnerships or other companies do they work with and integrate within their solutions? Are their partners also known for durable and reliable equipment?

- Expertise and Resources. Do they have a team of application and electrical engineers, software specialists, finance and production specialists and technical experts to provide knowledge in the many areas of order fulfillment and packaging? Can they evaluate efficiency, barriers and bottlenecks to provide you with solution options?

- Technical Support. Do they have an on-site technical support team? Are parts readily available? Do they have an easily accessible customer service support team?

Building Precision Solutions

At Baumfolder Solutions in Sidney, Ohio, our team of engineers and experts can integrate a new process or re-engineer an existing process to work seamlessly and improve efficiency in your order fulfillment and packaging line. We take a customized approach based on your needs and using our expertise to find the best solution to improve efficiency and capture value.

In today’s complex and global environment, efficiency needs to be top priority – always.

Whether your needs are document insertion or print and apply of personalized documents, we can provide a complete turnkey solution from design to delivery.