Anyone with experience in paper folding knows that feeding, and folding paper is not as easy as it sounds.

In fact there is a great deal of engineering and precision needed to achieve even the simplest of folds. Humidity, temperature and speed are just a few things that can wreak havoc on your folding production. Then there is the many different paper/ material stocks, grades, types, and thicknesses that each brings their own set of challenges.

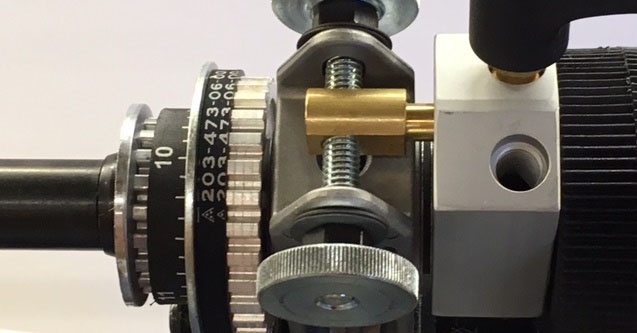

While setting up your next production run you need as many advantages as you can get to help combat the many challenges and obstacles that may come about. One of these very important and HUGE advantages is micro adjustments on fold plates. Everyfold plate comes with a pan stop adjusting knob to help rough in the size and type of fold you are trying to achieve, but micro adjustments move the entire paper stop and allows you to make smaller more precise adjustments. This is very important if you need to adjust and improve your fold while accounting for speed, temperature, and paper type. For more helpful tips please check out the resources page at www.Baumfolder.com.